Updates:-

- 28 Jun 11: I cant help but thank the kind guys at Texas Instruments. I cant believe my eyes, they have shipped me a sample of their instrumentation amplifier. Thats would help me simplify my input block. Thanks u guys… You rock.

- 01 Jul 11: Received Sample. Waiting for Farnell guys to ship my pressure sensors…

- 07 Jul 11 : Received Pressure sensors.

This project will describe building of a Pump control system. The requirement primarily arose to satiate the requirements of my parents, who have to manually switch on the pump every day morning and switch it off and continuously monitor the tank for overflow. So I have taken up the challenge onto myself...

However I would be ungrateful, I do not acknowledge the inputs I received after reading Kayne Richens blog post.

This blog is progressive ; hence will get updated as things progress.....

Lets me see how do things unfold...

Basic Design Objectives:-

Lets me see how do things unfold...

Basic Design Objectives:-

- Should be cheap and affordable.

- Should be as automated as possible requiring minimal user supervision.

- Should have a user-friendly MMI.

- Prevent water and electricity wastage.

- Erratic water supply timings.

- Non scheduled Electrical Load shedding .

- High head of water tank.

- Intelligent control system.

System Blocks Functions:-

Input Block:-

| Input Description | Sensor Type | Micro-controller Input |

|---|---|---|

| Sense Tank Capacity | Differential Pressure Sensor | Analog |

| Sense Electricity Availability | Optocoupler | Digital/Interrupt |

| Sense Time | RTC | Digital |

| Sense Input Water Supply Availability | Differential Pressure Sensor | Analog |

Output Block:-

| Output Description | Transducer Type | Micro-controller Output |

|---|---|---|

| Motor On/Off | Solid State Relay | Digital |

| Valve Solenoid On/Off | Relay | Digital |

| Alarm | Buzzer | Analog |

Mathematics for Selecting Differential Pressure Sensor:-

Why Differential Pressure Sensor?

A differential pressure sensor will eliminate variation in pressure due to changes in atmospheric pressure.

Mathematics

Capacity of Water Tank = 500 Lt

Water Tank Head = 30 Ft = 9.144 Mt = 914.4 Cm

Average Ambient Temperature = 25 deg Celcius

Specific Gravity of Tap water=0.997gm per cubic cm = 997Kg per cubic meter

Dia of Discharge Pipe=1/2 in = 1.27 Cm=0.0127 M

Pressure exerted at Base of Building by a column of Water at height

P = h * rho * g

where

P = Pressure

h = height of liquid column (2000 mm = 2m)

rho = Density of water (1000 kg/m^3)

g = Acceleration due to gravity (9.81 m/s^2)

P = Pressure

h = height of liquid column (2000 mm = 2m)

rho = Density of water (1000 kg/m^3)

g = Acceleration due to gravity (9.81 m/s^2)

P=9.14 x 997x 9.81 = 89394.4098 Pascals = 89.39kPa = 89.4 kPa (approx)

Similarly Pressure at Rooftop at the base of tank itself

P=1.5 x 997x 9.81 =14670.855 Pascals =14.67kPa = 14.7 kPa (approx)

Selected Sensor : Freescale Differential Pressure Sensor MPX2100DP 0-100 kPa

Selection of MCU:-

Family : Microchip PIC

Why : Because I have necessary experience and required development tools.

Max No of ADC Channels Required = 3 (2xpressure Sensor + 1 spare)

No of Interrupts : 02 (Electrical Supply Available & Float Valve)

Digital I/O = 8

Operating Voltage= 5V

SPI Required = Yes (For Interfacing RTC)

MCU Selected = 16F876A or 16F877A Why? Because I already have!

Design of Pressure Sensor Amplifier:-

Design Guide/Reference : -

- Op Amps for Everyone Design Guide.

Amplifier Design Objective : The output span of the transducer must be matched to the input span of the ADC to achieve optimum performance.

Mathematics for Amplifier Design

Mathematics for Amplifier Design

Span and Offset Characteristics at 10v,15v & 5V Excitation Voltage. As sensor is ratio-metric the the values are scaled for.

MPX2100DP

| Excitation Voltage | Min Span (mV) | Max Span (mV) | Min. Offset (mV) | Max Offset (mV) |

|---|---|---|---|---|

| 10V | 38.5 | 40 | -1 | 1 |

| 15V (scaled) | 57.75 | 60 | -1.5 | 1.5 |

| 5V (scaled) | 19.25 | 20 | -0.5 | 0.5 |

| 9V(scaled) | 34.65 | 3.6 | -0.9 | 0.9 |

MPX2010DP

| Excitation Voltage | Min Span (mV) | Max Span (mV) | Min. Offset (mV) | Max Offset (mV) |

|---|---|---|---|---|

| 10V | 24 | 26 | -1 | 1 |

| 15V (scaled) | 36 | 39 | -1.5 | 1.5 |

| 5V (scaled) | 12 | 13 | -0.5 | 0.5 |

| 9V(scaled) | 21.6 | 23.4 | -0.9 | 0.9 |

Desired Amplified Span and Offset

Desired Offset= 0.5V

Desired Span = 5V

Gain Range & Offset Calculation

Maximum Gain =Desired Span (V)

Sensor’s Minimum Span

Desired Span = 5V

| Excitation Voltage | Maximum Gain (MPX2100DP) | Maximum Gain (MPX2010DP) |

| 10V | =5/38.5 = 129.8 = 130 | 208 |

| 15V | =5/57.75 = 86.58 = 87 | 139 |

| 5V | =5/19.25 = 259.75 = 260 | 417 |

| 9V | =5/34.65=144.300=144 | 231 |

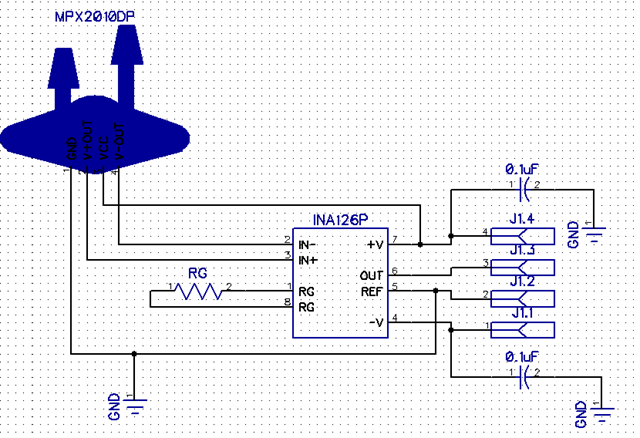

Since Texas Instruments was kind to ship me samples of their instrumentation amplifiers, I would be basing my calculations on same. There is no rocket science involved since the datasheet is fairly self explanatory and the instrumentation amplifier itself requires only one external component for gain adjustment.

Texas Instruments was generous in mailing following samples to me

INA126, INA128,INA122,INA2126

I would be using INA126 amplifier for testing purpose

Brief description about INA126 ..”The INA126 and INA2126 are precision instrumentation amplifiers for accurate, low noise differential signal acquisition. Theirtwo-op-amp design provides excellent performance with very low quiescent current (175µA/channel). This, combined with awide operating voltage range of ±1.35V to ±18V, makes them ideal for portable instrumentation and data acquisition systems. Gain can be set from 5V/V to 10000V/V with a single external resistor. Laser trimmed input circuitry provides low offset voltage (250µV max), low offset voltage drift (3µV/°C max) and excellent common-mode rejection.”

Gain calculation formulae

| Instr Amplifier | Gain Formula |

| INA 122 | G=5+200kΩ RG |

| INA 126 | G=5+80kΩ RG |

| INA 128 | G=1+50kΩ RG |

RG (IN OHMS)values at Max Gain. Values in (brackets) indicate nearest standard resistor values.

MPX2100DP

| Instr. Amplifier | 10V | 15V | 5V | 9V |

| INA 122 | 1602 Ω (1.6KΩ) | 2452Ω(2.4KΩ) | 785Ω (750Ω) | 1439Ω(1.5K) |

| INA 126 | 641Ω (620Ω) | 981Ω (1kΩ) | 584Ω (560Ω) | 576Ω(560Ω) |

| INA 128 | 388Ω (390Ω) | 548Ω (560Ω) | 193Ω (180Ω) | 347Ω(360Ω) |

MPX2010DP

| Instr. Amplifier | 10V | 15V | 5V | 9V |

| INA 122 | 984 Ω (1KΩ) | 1494Ω(1.5KΩ) | 486Ω (470Ω) | 885Ω(820Ω) |

| INA 126 | 393Ω (390Ω) | 598Ω (560kΩ) | 194Ω (200Ω) | 356Ω(360Ω) |

| INA 128 | 241Ω (240Ω) | 363Ω (360Ω) | 120Ω (120Ω) | 214Ω(200Ω) |

Amplifier Interface Design

![\includegraphics[scale=0.500000]{ckt8.1.1.ps}](http://www.ece.rice.edu/~jdw/243_lab8/img57.png)

In the MPX sensor, each of the resistors in the bridge is an active strain gage, so this design illustration is applicable for the amplifier design.

Test Schematic

3D PCB Render (Using Diptrace)

No comments:

Post a Comment